Choosing the right roofing material is one of the most crucial decisions for any construction project. In today’s competitive market, upvc roofing sheet vs gi sheet remains a hot topic for homeowners, contractors, and industry professionals alike. This article provides an in-depth analysis of the two popular options—uPVC roofing sheets and GI (Galvanized Iron) sheets. We’ll explore their distinct features, performance in various environments, installation complexities, cost implications, and long-term sustainability. By delving into these aspects, you’ll be empowered to make an informed decision that best meets your project requirements.

With the ever-evolving construction standards, both uPVC and GI sheets have their unique merits. uPVC roofing sheets are known for their excellent resistance to harsh weather, energy efficiency, and low maintenance requirements. On the other hand, GI sheets bring the time-tested strength and durability of metal, particularly in environments where structural integrity is paramount. In the following sections, we break down every element of these materials in a detailed yet reader-friendly manner, ensuring that even a beginner can grasp the essentials. Let’s embark on this exploration and discover which option reigns supreme in various categories.

1. Understanding uPVC Roofing Sheets

uPVC, or Unplasticized Polyvinyl Chloride, is a robust and rigid plastic that’s been increasingly used in modern construction, particularly in roofing applications. Unlike traditional PVC, uPVC does not contain plasticizers, which makes it exceptionally stable and durable under varied environmental conditions.

Key Properties of uPVC Roofing Sheets

- Durability: uPVC is highly resistant to weathering, corrosion, and chemical damage. This makes it ideal for areas with high humidity or where saline conditions prevail.

- Energy Efficiency: Due to its low thermal conductivity, uPVC roofing sheets provide excellent insulation, thereby reducing energy consumption and maintaining a comfortable indoor climate.

- Low Maintenance: One of the standout benefits is the minimal upkeep required. A simple cleaning routine is usually enough to keep the sheets in prime condition.

- Aesthetic Versatility: Available in a range of colors and finishes, uPVC sheets can mimic traditional roofing materials, offering both functionality and visual appeal.

Common Usage

uPVC roofing sheets are widely used across various sectors. In residential settings, they are often chosen for their cost-effectiveness and ease of installation. Commercial and industrial projects also benefit from uPVC’s insulating properties and durability. Furthermore, its lightweight nature means that the overall load on the structure is reduced, which is particularly beneficial in retrofit projects.

Advantages in Construction

The benefits of uPVC are far-reaching:

- Enhanced Insulation: Its ability to reduce heat transfer helps maintain a consistent indoor temperature, which is especially useful during extreme weather conditions.

- Environmental Resistance: uPVC is impervious to moisture, which significantly lowers the risk of mold or mildew—common issues in humid climates.

- Economic Value: While the initial cost may be slightly higher than some alternatives, the long-term savings in energy bills and reduced maintenance costs make uPVC a financially sound investment.

- Ease of Installation: The lightweight and manageable size of uPVC sheets mean that they can be installed quickly with minimal labor, saving both time and money.

However, like any material, they have their pros and cons. For a detailed breakdown of the advantages and disadvantages of uPVC roofing sheets, read our in-depth guide.

Considerations

Despite its many benefits, there are factors to be mindful of when opting for uPVC roofing sheets:

- Fading: Over prolonged exposure to intense sunlight, the color of uPVC sheets may fade, which can impact the aesthetic appeal.

- Flexibility: While uPVC is rigid, it may not offer the same structural strength as metals in situations where extreme load-bearing capacity is required.

- Environmental Impact: Although uPVC is recyclable, its production involves chemical processes that need to be managed responsibly to minimize environmental impact.

In summary, uPVC roofing sheets offer a compelling combination of durability, energy efficiency, and low maintenance, making them an excellent choice for various roofing applications. Their versatility and economic benefits make them especially attractive for both new constructions and renovations.

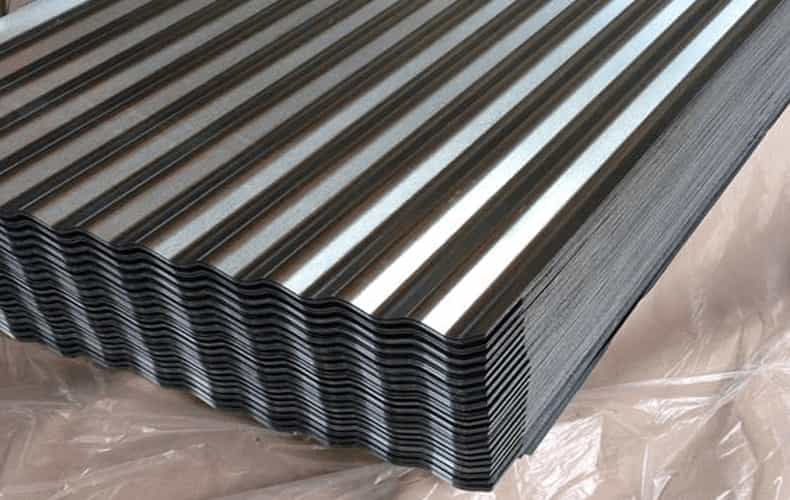

2. Understanding GI (Galvanized Iron) Sheets

GI sheets, often known as Galvanized Iron sheets, have long been a staple in the construction industry. Known for their impressive strength and durability, GI sheets have been used extensively in both residential and industrial projects. These sheets are produced by coating iron or steel with a layer of zinc, which provides a robust barrier against corrosion.

Key Characteristics of GI Sheets

- Strength and Longevity: GI sheets are celebrated for their structural integrity. They can withstand high loads and harsh weather conditions, making them particularly suitable for large-scale projects.

- Corrosion Resistance: The galvanization process significantly enhances the corrosion resistance of the metal. However, in extremely humid or coastal areas, additional protective coatings might be necessary.

- Thermal Conductivity: Unlike uPVC, GI sheets have a higher thermal conductivity. This means they tend to absorb and transfer heat quickly, which can lead to higher indoor temperatures unless proper insulation is applied.

- Aesthetic Flexibility: GI sheets offer a sleek, modern look that many architects and designers favor. With various coatings and finishes available, these sheets can be adapted to suit diverse design preferences.

Usage and Benefits

GI sheets are ideal for projects that demand high structural strength. They are commonly used in industrial buildings, warehouses, and large-scale commercial structures. Their robustness makes them a popular choice for roofing systems where durability is the primary concern. Additionally, the reflective properties of GI sheets can help mitigate solar heat gain when paired with proper insulation.

Advantages in Structural Applications

- Enhanced Load-Bearing Capacity: GI sheets provide superior support, especially in areas where heavy roofing loads are anticipated.

- Longevity: With proper maintenance, GI sheets can last for decades, making them a long-term solution for many construction projects.

- Fire Resistance: Metal roofing, including GI sheets, is inherently fire-resistant. This property adds an extra layer of safety to buildings, particularly in fire-prone regions.

- Recyclability: GI sheets are recyclable, which aligns with sustainable building practices and reduces the overall environmental footprint.

Limitations to Consider

While GI sheets have many strengths, they are not without drawbacks:

- Weight: GI sheets are considerably heavier than uPVC, which may necessitate additional structural support and complicate the installation process.

- Maintenance Needs: Over time, even galvanized coatings can deteriorate, leading to rust and corrosion if not properly maintained. This can involve periodic inspections and additional maintenance expenses.

- Heat Absorption: The high thermal conductivity means that without adequate insulation, buildings may experience increased heat, potentially raising cooling costs during hot seasons.

- Initial Cost: Although GI sheets are durable, the upfront costs for high-quality galvanized metal can be significant compared to other materials.

GI sheets continue to be a trusted choice in the construction industry, particularly for projects where strength, longevity, and fire resistance are critical. Their robust nature makes them indispensable in scenarios that demand superior structural performance.

3. Comparative Analysis: Durability, and Cost-Effectiveness

When comparing upvc roofing sheet vs gi sheet, several critical factors come into play. In this section, we delve into the durability, thermal insulation properties, and cost-effectiveness of both materials to provide you with a well-rounded perspective.

Durability and Weather Resistance

uPVC Roofing Sheets:

- Resilience: uPVC excels in resisting harsh environmental conditions. It does not corrode or rust, making it ideal for coastal areas and humid climates.

- Longevity: With minimal wear and tear over time, uPVC offers a long lifespan with little degradation.

- Maintenance: The low-maintenance nature of uPVC ensures that it remains effective with just routine cleaning.

GI Sheets:

- Strength: GI sheets are inherently strong, capable of withstanding heavy loads and extreme weather conditions.

- Corrosion: Although the zinc coating offers good protection, GI sheets may still be vulnerable to rust over time, especially in very moist or salty environments.

- Structural Integrity: For projects that require high structural strength, GI sheets deliver unparalleled support, albeit with a need for periodic maintenance.

Energy Efficiency

uPVC Roofing Sheets:

- Insulating Properties: One of the standout features of uPVC is its low thermal conductivity. This helps maintain cooler indoor temperatures during hot weather, reducing reliance on air conditioning.

- Energy Savings: The superior insulation offered by uPVC translates to lower energy bills, which is a significant long-term benefit.

- Comfort: Homeowners often report improved indoor comfort levels due to the effective thermal insulation provided by uPVC sheets.

GI Sheets:

- Heat Conduction: GI sheets tend to absorb heat rapidly, which can result in higher internal temperatures. This may require additional insulation layers to mitigate the effect.

- Reflectivity: When properly coated or painted with reflective finishes, GI sheets can reduce heat absorption somewhat, but they still generally lag behind uPVC in thermal performance.

- Supplementary Insulation: To achieve energy efficiency similar to uPVC, GI roofing systems often need extra insulation, which can add to the overall cost and complexity.

Cost-Effectiveness and Long-Term Investment

uPVC Roofing Sheets:

- Initial Investment: uPVC sheets might have a moderately higher initial cost compared to some traditional options. However, the overall investment is balanced by low maintenance expenses.

- Long-Term Savings: Due to their durability and energy efficiency, uPVC sheets typically result in significant savings over the lifespan of the roof.

- Installation: The lightweight nature of uPVC leads to reduced labor costs during installation, further enhancing its cost-effectiveness.

GI Sheets:

- Upfront Cost: GI sheets can be more expensive initially, especially when considering the quality of the galvanization process and additional protective coatings.

- Maintenance Expenses: Over time, the need for periodic maintenance and potential repainting or re-coating to prevent rust can drive up the long-term costs.

- Value Proposition: Despite the higher initial cost, GI sheets offer excellent durability and structural strength, making them a worthwhile investment for projects where these factors are paramount.

Summarized Comparison Table

| Feature | uPVC Roofing Sheets | GI Sheets |

|---|---|---|

| Durability | Highly resistant to corrosion; long-lasting | Extremely strong; may require periodic maintenance |

| Thermal Insulation | Excellent, reduces energy costs | High heat absorption; needs additional insulation |

| Cost-Effectiveness | Lower maintenance; energy-efficient, saving in the long run | Higher upfront and maintenance costs; robust performance |

| Installation | Lightweight, easier and quicker to install | Heavier, may require extra support and labor |

| Environmental Impact | Recyclable, energy efficient | Recyclable, but more resource-intensive production |

In summary, both uPVC roofing sheets and GI sheets have their unique advantages and challenges. The upvc roofing sheet vs gi sheet debate ultimately comes down to specific project requirements—whether the priority is on low maintenance and energy efficiency (uPVC) or on structural strength and durability (GI). For many modern applications, especially where thermal insulation and long-term cost savings are essential, uPVC emerges as the preferred choice. Conversely, GI sheets are unmatched when it comes to providing robust structural support and fire resistance.

4. Installation, Aesthetic, and Structural Considerations

Selecting between uPVC and GI roofing isn’t just about performance metrics—it’s also about the practical aspects of installation, design, and how each material fits into your overall architectural vision.

Ease of Installation

uPVC Roofing Sheets:

- Lightweight: Their low weight simplifies handling and installation, often requiring less manpower.

- Flexible Fitting: uPVC sheets can be cut and fitted easily, adapting to various roof shapes and sizes.

- Speed: Quick installation times translate into reduced labor costs and minimal disruption to the construction schedule.

GI Sheets:

- Heavier Material: GI sheets are more cumbersome to handle, which might require additional equipment or skilled labor.

- Precision Required: The installation process for GI sheets demands careful alignment to ensure that the galvanized coating remains intact, preventing future corrosion.

- Reinforcement Needs: Due to their weight, the underlying structure may need additional reinforcement, which could increase overall project costs.

Aesthetic Appeal

uPVC Roofing Sheets:

- Modern Look: uPVC offers a clean and modern aesthetic, often available in a variety of colors and finishes.

- Versatility: They can be designed to mimic other traditional roofing materials, providing a balance between contemporary style and classic charm.

- Long-Lasting Color: Many uPVC products are treated to resist fading, keeping the roof looking vibrant for years.

GI Sheets:

- Industrial Charm: GI sheets provide a sleek, industrial look that is highly valued in modern commercial and urban architectural designs.

- Custom Finishes: With various coatings and painting options available, GI sheets can be tailored to match almost any color scheme or design requirement.

- Texture and Depth: The inherent metallic texture of GI sheets adds a unique depth and sophistication to the building’s overall appearance.

Structural Considerations

uPVC Roofing Sheets:

- Load Reduction: Their lightweight nature eases the structural load on the building, potentially lowering the need for heavy-duty support structures.

- Thermal Stability: uPVC’s low thermal conductivity not only contributes to energy efficiency but also minimizes expansion and contraction issues that can lead to structural stress.

- Flexibility: uPVC’s slight flexibility can absorb minor structural movements without cracking.

GI Sheets:

- Robust Support: Designed to bear significant loads, GI sheets excel in applications where structural integrity is critical.

- Rigidity: Their rigid nature ensures that the roofing system remains stable under heavy wind or storm conditions.

- Long-Term Performance: With proper maintenance, GI sheets maintain their structural integrity over decades, even in challenging environments.

Taking all these factors into account, the decision between uPVC roofing sheets and GI sheets should align with the overall design philosophy, structural needs, and aesthetic goals of your project. While uPVC is favored for its ease of installation and energy-saving benefits, GI sheets stand out for their robust structural performance and modern industrial appeal.

FAQs

Q1: What is the primary difference between uPVC roofing sheets and GI sheets?

A1: The main difference lies in the material properties. uPVC roofing sheets are lightweight, energy-efficient, and require low maintenance, whereas GI sheets are heavy, extremely durable, and offer superior structural strength. The choice depends on whether you prioritize ease of installation and insulation (uPVC) or robustness and load-bearing capacity (GI).

Q2: Which option is more cost-effective in the long run?

A2: Although uPVC roofing sheets may have a higher initial cost in some cases, they generally prove more cost-effective over time due to lower maintenance expenses and energy savings. GI sheets, while durable, often incur higher upfront costs and require periodic maintenance to prevent corrosion.

Q3: How do uPVC roofing sheets perform in extreme weather conditions?

A3: uPVC sheets excel in resisting harsh weather elements. They are highly resistant to corrosion, UV rays, and moisture, making them ideal for coastal and humid regions. Their excellent thermal insulation helps in maintaining indoor comfort during extreme temperature fluctuations.

Q4: Can GI sheets be used in residential applications?

A4: Yes, GI sheets are often used in residential projects, especially in designs that favor a modern, industrial look. However, due to their higher thermal conductivity and weight, additional insulation and structural support may be necessary compared to uPVC installations.

Q5: What are the environmental implications of using uPVC vs. GI sheets?

A5: uPVC roofing sheets are recyclable and offer significant energy efficiency benefits, reducing the overall carbon footprint. GI sheets are also recyclable, but their production is more resource-intensive. The choice ultimately depends on balancing performance with sustainable building practices.

Q6: How does the installation process differ between the two materials?

A6: uPVC roofing sheets are lighter and easier to install, often requiring fewer labor resources. In contrast, GI sheets are heavier, necessitating additional structural support and specialized installation techniques to ensure proper alignment and long-term durability.

Final Thoughts

In the debate of upvc roofing sheet vs gi sheet, both materials bring distinct advantages to the table. uPVC roofing sheets offer outstanding energy efficiency, low maintenance, and easy installation, making them ideal for projects where cost-effectiveness and thermal insulation are priorities. Conversely, GI sheets provide unmatched structural strength, durability, and an industrial aesthetic, making them perfect for large-scale or heavy-duty applications.

When choosing between the two, consider the specific demands of your project—whether you need a lightweight, energy-saving solution or a robust, long-lasting roofing system capable of withstanding extreme conditions. Both options have their place in modern construction, and with the right maintenance and installation practices, either can provide years of reliable performance.

Ultimately, making an informed decision means weighing the pros and cons of each material against your project requirements, budget, and design vision. With the comprehensive insights provided in this article, we hope you now have a clearer understanding of how uPVC roofing sheets and GI sheets stack up against each other.